ZWG S.A. Iwiny is a producer of high-quality rubber linings for ball and cylpeps mills.

The construction of the linings guarantees an increase in the profitability of the production process, an improvement in milling efficiency and protection from wear.

Their durability is decidedly greater that the surfaces used in the past: cast steel or synthetic plates (such as EPU), basalt blocks etc. This is achieved by using excellent wear-resistant rubber. An additional effect of the use of rubber linings is a significant reduction in noise, which improves the work environment surrounding the mill.

Advantage of rubber linings

|

Greater load mass |

→ | An increase in the mill’s working volume results from the difference in volume between traditional and rubber linings. |

|

Greater mill output |

→ |

Optimisation of the milling process through the use of the correct structure of rubber linings – in particular for lifting parts – and the increase in the mill load result in a increase in the output of the milling process. |

|

Energy savings |

→ |

Optimisation of the milling process, the lower weight of the rubber lining and cost shorter crushing times results in lower energy use. |

|

Lower use of grinding media |

→ |

The properties of the rubber linings cause lengthen the service life of grinding media. |

|

Extended operation time |

→ |

The extension of the time between refurbishments by 2 to 6 times. |

|

Shortening of refurbishment time |

→ |

Simple method for installation of linings and low weight of unified parts allow radically shortened refurbishment times. |

Examples of products

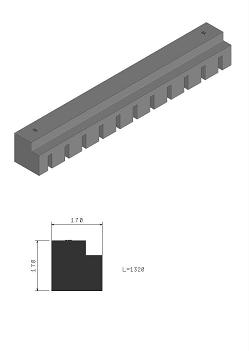

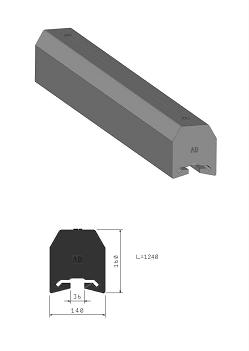

Drum rim

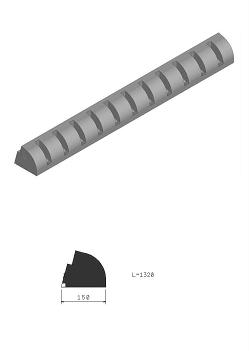

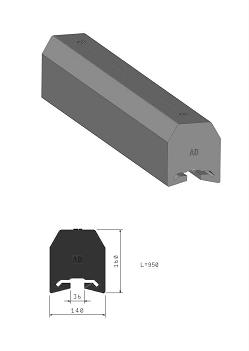

End cap rim

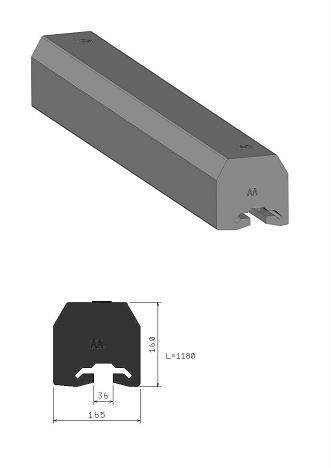

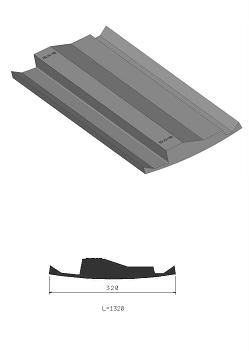

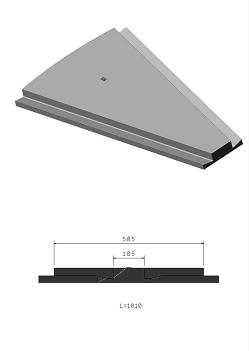

Drum plate

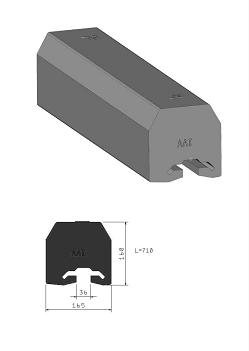

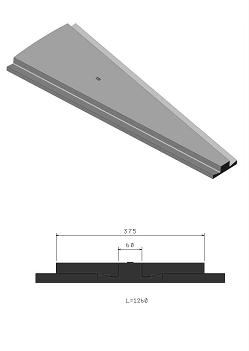

End cap plate

Internal ring