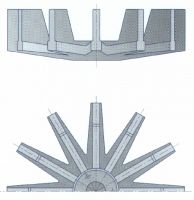

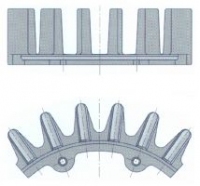

We produce complete rubber parts assemblies for floatation machines, rotor diameter 680-1480mm, in types, series IZ and PM.

These types of assemblies differ in a fundamental way, both in terms of the shape of the rotor and the calming zone, as well as in the form and the manner of fastening the floatation cell.

In IZ-type machines, unreinforced moulded profiles are used, and are fastened to the walls of the floatation cell with rubberised steel trim.

In PM-type machines, 10 mm-thick tiles with a 2 mm-thick vulcanised steel sheet have been used for the construction of the floatation cell.

This type of liner is fastened to the body using screws with rubberised heads. The entire assembly is made from wear-resistant rubber mixtures.

floatation